Importance of Drill Bits in Blast Furnace Operations

During the smelting process of the blast furnace, it will continuously produce the pig iron and slag accumulated in the hearth. Opening the iron hole on time and discharging the slag and taping the iron, then the space can be re-formed to accommodate the continuously generated slag and iron, so as to ensure the continuous production of the blast furnace. The quality of the drill is related to the quality of the opening effect. It will directly affect the amount of iron and slag, and affects the maintenance of the tap hole. Therefore, the blast furnace drill bits are the important spare parts for the production.

Continuous Improvement and Production Technology

Through the actual use of the equipment on the production site, our team constantly transforms and improves the spare parts in front of the furnace. Now the specialized production technology of blast furnace drill pipes and drill bits has been formed. According to the effect of torsional pressure, bending, friction and other supportive pressure on the drill bits under a high temperature environment, we improve the chemical composition and production process of the drill bits to increase the working life of the drill bit in the high temperature environment.

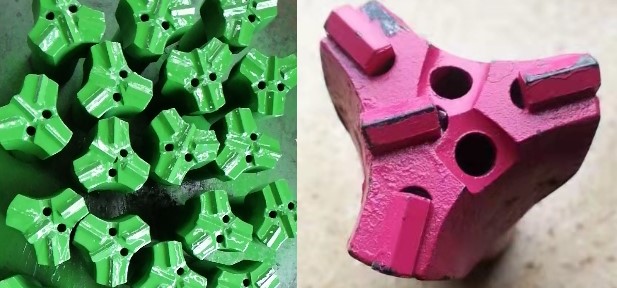

Composition and Material of Blast Furnace Drill Bits

The blast furnace bits are mainly composed of the steel body and tungsten carbide bit.The composite blast furnace bit needs to consider the rigidity of the fixed teeth, wear resistance and brazing strength of the head of the drill body and the heat treatment relationship of drill bits from high temperature to normal temperature. Generally, chromium molybdenum low carbon alloy steel is used, and the alloy head of the drill bit is made of tungsten carbide

About - Drill bits

Drill bits and drill pipes play an important function in keeping the continuous and green operation of blast furnaces. Their quality immediately affects the hole impact, slag discharge, and universal furnace performance. With superior generation, durable substances, and improved manufacturing tactics, Hotion group ensures that each drill bit plays reliably beneath excessive temperatures and heavy workloads. By choosing precision-engineered drill bits and pipes, industries can attain strong production, lessen protection, and make the lifespan in their furnace device.

.png?v=20260202)